Dyfuzory dyskowe STADYSKFLEX 250 – skuteczne i energooszczędne napowietrzanie ścieków i wody

Nowoczesne rozwiązanie dla oczyszczalni i zbiorników wodnych

Dyfuzory dyskowe STADYSKFLEX 250 to wysokiej klasy urządzenia przeznaczone do drobnopęcherzykowego napowietrzania ścieków i wody. Produkowane z atestowanych, wytrzymałych materiałów, gwarantują niezawodność, trwałość oraz wysoką efektywność natleniania. Dzięki niskiemu oporowi przepływu powietrza oraz doskonałemu transferowi tlenu, nasze dyfuzory pozwalają na oszczędność energii elektrycznej, co czyni je idealnym wyborem w ekologicznych instalacjach uzdatniania wody.

Zastosowanie dyfuzorów STADYSKFLEX 250

Dyfuzory talerzowe marki STAGUM-EKO wykorzystywane są w:

-

komunalnych i przemysłowych oczyszczalniach ścieków,

-

zbiornikach technologicznych i buforowych,

-

akwariach, stawach hodowlanych i fontannach,

-

zbiornikach do uzdatniania wody pitnej (wersja STADYSKFLEX 250 W),

-

rekultywacji jezior, stawów i kąpielisk.

Dzięki możliwości pracy zarówno w trybie ciągłym, jak i przerywanym, dyfuzory STADYSKFLEX zapewniają elastyczność w działaniu oraz dopasowanie do różnych systemów napowietrzających.

Charakteryzują się zarówno niskim oporem przepływu powietrza, i jednocześnie wysokim transferem tlenu do oczyszczania ścieków.

Wersja STADYSKFLEX 250 W – do wody pitnej i specjalistycznych zastosowań

Model STADYSKFLEX 250 W, wykonany z białej gumy EPDM, przystosowany jest do stosowania w urządzeniach do uzdatniania wody pitnej. Może być zasilany zarówno sprężonym powietrzem, jak i czystym tlenem, co czyni go idealnym rozwiązaniem w specjalistycznych reaktorach i procesach technologicznych, gdzie wymagana jest wysoka czystość i precyzyjne natlenianie.

Filtrosy mogą być stosowane bez wątpienia w reaktorach, w których niezbędnym jest, zastosowanie tlenu z powietrza bądź czystego tlenu. Niezależnie od tego, dyfuzory nasze pracują we wszelkiego rodzaju zbiornikach, w których niezbędne jest użycie powietrza do celów technologicznych.

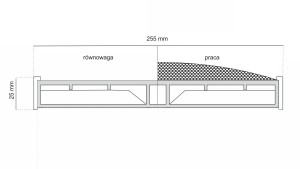

Charakterystyka dyfuzora dyskowego „STADYSKFLEX 250”

- Nośnik membrany – polipropylen wzmocniony włóknem szklanym

- Membrana – guma z kauczuków EPDM

- Opaska mocująca – stal kwasoodporna 1.4404

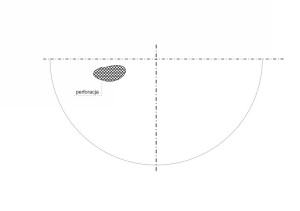

- Średnica dyfuzorów 250 mm

- Powierzchnia czynna dyfuzora 408 cm2

- Masa dyfuzora z łącznikiem 0,45 kg

- Ciśnienie otwierające membranę ok.120 mm H2O

- Przepływ powietrza przez dyfuzor 0,5-6 Nm3/h

- Wydajność natleniania w warunkach standardowych ok.20g O2 /Nm3 na 1 metr

- Ekonomia natleniania w warunkach standardowych 3,0 – 6,5 kg O2/kWh

- Dyfuzory mogą pracować od 1,0 do 10 m słupa ścieków

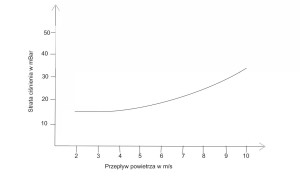

- Opór przepływu powietrza w zakresie wydajności dyfuzora w temp. 20oC

w zakresie od 1m3/h do 6m3/h zmienia się od 20 do 35 hPa - Temperatura powietrza dla dyfuzora z membraną standardową – do 80oC

- Temperatura powietrza dla dyfuzora z membraną specjalną – do 120oC

Nasze dyfuzory dyskowe mogą być wykorzystywane przede wszystkim w komunalnych, przemysłowych oczyszczalniach ścieków, akwenach hodowli ryb, do oczyszczania jezior, stawów i kąpielisk. Działają one w dwóch cyklach: zarówno ciągłym, jak i przerywanym.

Dyfuzory dyskowe a oszczędność energii

Dzięki niskim oporom przepływu i wysokiej skuteczności przenoszenia tlenu, dyfuzory dyskowe STAGUM-EKO znacząco obniżają zużycie energii. To rozwiązanie:

-

przyjazne środowisku,

-

ekonomiczne dla oczyszczalni ścieków,

-

wydajne nawet w wymagających warunkach eksploatacyjnych.

Membrany produkowane są z naszej autorskiej mieszanki gumy na bazie kauczuków EPDM, co przekłada się na ich trwałość, elastyczność oraz odporność na zużycie.